We love manufacturing and believe it reflects the God-given characteristics of creativity, ingenuity, teamwork, and the application of man’s greatest gifts and talents. Our customers are small to middle market manufacturers that desire a strong engineering partner to assist in the design, engineering, tooling, and manufacturing of plastic components. We believe that custom injection molding is a service to our customers that requires close communication and collaboration. To be the biggest company is not our goal, but to find pleasure in the business of custom injection molding by personally knowing every customer, employee, and vendor and to create great value manufacturing useful products for and with people we enjoy.

Texas Injection Molding provides injection molding manufacturing services to a wide range of industries and applications.

Texas Injection Molding supports customer applications with engineering support, complete in-house tooling resources, and technical process engineering for the development of molding processes.

What is plastic injection molding?

Injection molding is the most commonly used manufacturing process for making plastic parts. Injection molding can be completed with a host of materials, most commonly thermoplastic and thermosetting polymers.

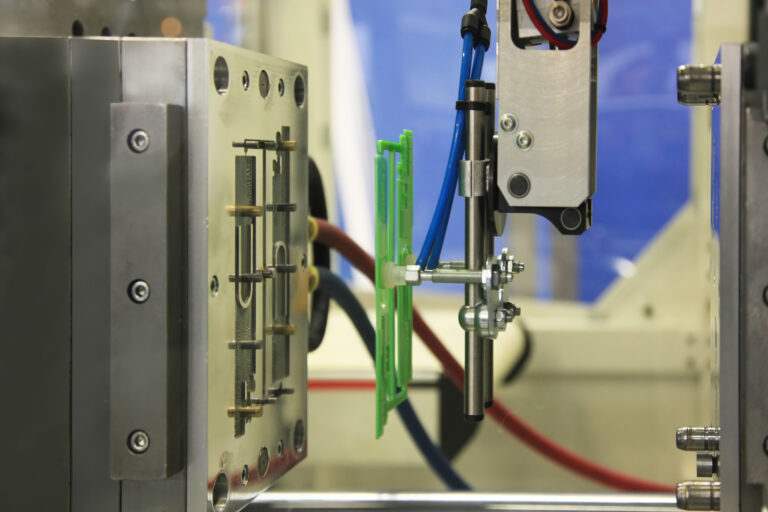

Injection molding requires an injection molding machine, plastic raw material, and an injection mold. The raw plastic material is melted in the injection unit and then “shot”/injected rapidly into the mold under high pressure. The plastic material is cooled by circulating water through the mold to transfer and remove the heat from the steel mold, part solidifies as cooled, the mold opens and the part is ejected from the cavity of the mold. The entire process or “cycle” is completed in seconds and then repeated.

The key steps in injection molding:

- Clamping: The mold’s two sides are sealed shut under hydraulic pressure.

- Screw Recovery: Plastic material is fed into the barrel and conveyed via rotating screw down the barrel toward the front of the screw. As the material is conveyed it is heated to the specified melt temperature creating the “shot” or volume of material to be injected.

- Injection: Screw is pushed forward injecting the material under very high pressure into the mold.

- Cooling: Water circulated through channels in the mold to remove heat and solidifies the molded part.

- Ejection: The clamp releases, mold opens and part is ejected from the mold.

Benefits of plastic injection molding

Plastic injection molding is ideal for producing high volumes of the same object.

- Parts can have complex geometries

- Highly efficient and repeatable manufacturing processes

- Automation means lower costs

- Variety of material choices can be used

Broad application experience to support your product

Plastic injection molding is used to create thousands of items used by millions people each and every day. Texas Injection Molding brings decades of experience in engineering and manufacturing products in many industries to your product.

Some of the industries we currently serve include:

- Energy

- Transportation

- Industrial

- Consumer

- Medical

- Food processing

- Safety

- Construction

- Agricultural

- Electronics and Business equipment

- Sports and outdoor equipment

Full-Service Manufacturing Resource

Our dedicated team combines decades of industry experience in engineering, tooling, processing, quality and maintenance with state-of-the-art technology to deliver quality plastic injection molding parts and remarkable plastic injection molding service to our customers.

- Plastic product design and engineering support

- 29 plastic injection molding machines ranging from 55 tons to 1000 tons

- Capacity to operate three shifts a day, five to seven days a week

- Tooling services for maintenance, repairs, and insert changes

- Multiple core pull, hand-loaded cores and automatic unscrewing cores

- Insert and over molding

- Plastic printing and plastic part decoration

- Secondary plastic machining, assembly and packaging

- ISO 9001:2015 certified

A Strategy that Delivers Service

Texas Injection Molding follows a simple strategy founded on People, Process and Technology. Our strategy in bonded by a culture of respect and genuine concern for others and is the “secret sauce” that makes us different.

People

- Our team of plastic engineering professionals support customer applications with decades of industry experience

- Our tooling and technical application team provide solutions to product revisions and advancements in automation and assembly.

- We partner with the world’s leading resin manufacturers and custom compounders to deliver deep technical resources in the areas of custom resin applications and testing.

Process

- Manufacturing operations are certified to ISO 9001:2015 standards

- Manufacturing processes for every part are optimized and qualified to repeatable standards prior to releasing to production.

- Molding machines and tooling are calibrated and managed to established MRO standards

- Materials are certified and lot tracked by barcode

- Every machine and key processing parameter is measured, reported and recorded in real time.

Technology

- We provide and maintain modern production technology and tools for our processing technicians to work efficiently.

- Our systems provide real time access to inventory, scheduling, machine utilization and many other factors to help us meet our client requirements.

- Broad press range to accommodate 55 to over 1,000 tons

- Automation inside and outside the tool, printing, sonic welding, assembly and custom packaging.

If we can help you with your project please call us at 281 489-4292 or use our Contact Form.