What is plastic blow molding?

Plastic blow molding is the common practice for molding plastic into hollow shapes. Plastic blow molding is used in many industries to manufacture a variety of bottles, containers and other hollow parts. In many applications the blow molding occurs at the filling lines for milk, water, soda, oil, chemicals or other liquids. Standard blow molding bottles such as small spray bottles, quart sized decanters or gallon jugs can be purchased through distribution. Texas Injection Molding manufactures custom blow molding applications where stock bottles are not acceptable or filling is done off-line.

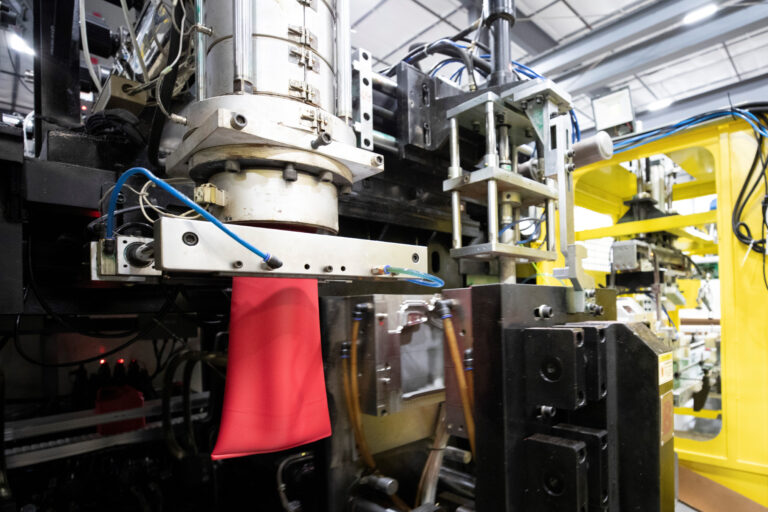

Blow molding requires a blow molding machine, plastic raw material, and the mold. The raw plastic material is melted in the injection unit and then extruded in the form of a tube called a parison. The mold is clamped around the hot parison and air is injected into the parison to inflate the plastic to conform to the mold. Chilled water is circulated through the mold to cool the part. Once cooled the mold opens up and ejects the part and the process of extruding the next parison repeats. The areas that were pinched during the process of clamping the mold on the parison is trimmed or “de-flashed.” If the end product is designed to have an opening such as a bottle, the opening is also trimmed.

The key steps in blow molding:

- Plastic pellets are fed into the machine hopper.

- Extrusion: Screw turns within heated barrel to extrude the parison.

- Clamping: The mold’s two sides are clamped around the parison.

- Blow Molding: Air is injected in the parison to inflate the plastic to the shape of the mold

- Cooling: Water circulated through channels in the mold to remove heat and solidifies the molded part.

- Trimming: If required, the “flash” or area pinched by the mold is trimmed.

Benefits of plastic blow molding

Plastic blow molding is used when you need a hollow part that cannot be produced by injection molding or other manufacturing processes. Blow molding is a cost effective method for production high volumes of parts. ideal for producing high volumes of the same object.

- Parts can be clear or colored

- Parts can have complex geometries

- Highly efficient and repeatable manufacturing processes

- Automation means lower costs

- Variety of material choices can be used

Broad application experience to support your product

Plastic Blow molding is used to create thousands of items used by millions people each and every day. Texas Injection Molding brings decades of experience in engineering and manufacturing products in many industries to your product.

Common examples of plastic blow molded products include:

- Plastic bottles (water, soda, oil, chemicals, milk, medicine

- Plastic canisters (Gas, water, chemicals)

- Plastic barrels

- Plastic tanks

- Toys and sporting goods

Full-Service Manufacturing Resource

Our dedicated team combines decades of industry experience in engineering, tooling, processing, quality and maintenance with state-of-the-art technology to deliver quality plastic injection molding parts and remarkable plastic injection molding service to our customers.

- Plastic product design and engineering support

- Blow molding capacity up to 3 gallons.

- Capacity to operate three shifts a day, five to seven days a week

- Tooling services for maintenance, repairs, and insert changes

- Custom labeling, plastic printing and plastic part decoration

- ISO 9001:2015 certified

A Strategy that Delivers Service

Texas Injection Molding follows a simple strategy founded on People, Process and Technology. Our strategy in bonded by a culture of respect and genuine concern for others and is the “secret sauce” that makes us different.

People

• Our team of plastic engineering professionals support customer applications with decades of industry experience

• Our blow molding tooling and technical application team provide solutions to product revisions and advancements in automation and assembly.

• We partner with the world’s leading resin manufacturers and custom compounders to deliver deep technical resources in the areas of custom resin applications and testing.

Process

• Plastic blow molding operations are certified to ISO 9001:2015 standards

• Manufacturing processes for every part are optimized and qualified to repeatable standards prior to releasing to production.

• Blow molding machines and tooling are calibrated and managed to established MRO standards

• Plastic blow molding Materials are certified and lot tracked by barcode

• Every blow molding machine and key processing parameter is measured, reported and recorded in real time.

Technology

• We provide and maintain modern plastic molding technology and tools for our processing technicians to work efficiently.

• Our systems provide real time access to inventory, scheduling, machine utilization and many other factors to help us meet our client requirements.

• We have the ability to monitor, maintain and measure precise wall thickness on blow molded products.

If we can help you with your project please call us at 281 489-429.