Identify, protect and track valuable assets with embedded RFID. Texas Injection Molding collaborates with leading RFID hardware and Systems Integrators to bring the experience of plastic injection molding to embedded RFID.

Custom plastic injection molded RFID tags allow for RFID to be utilized in harsh environments and provide superior resistance to water, salt, petroleum, chemical and resistance to shock, vibration, and high pressure and extreme temperature environments.

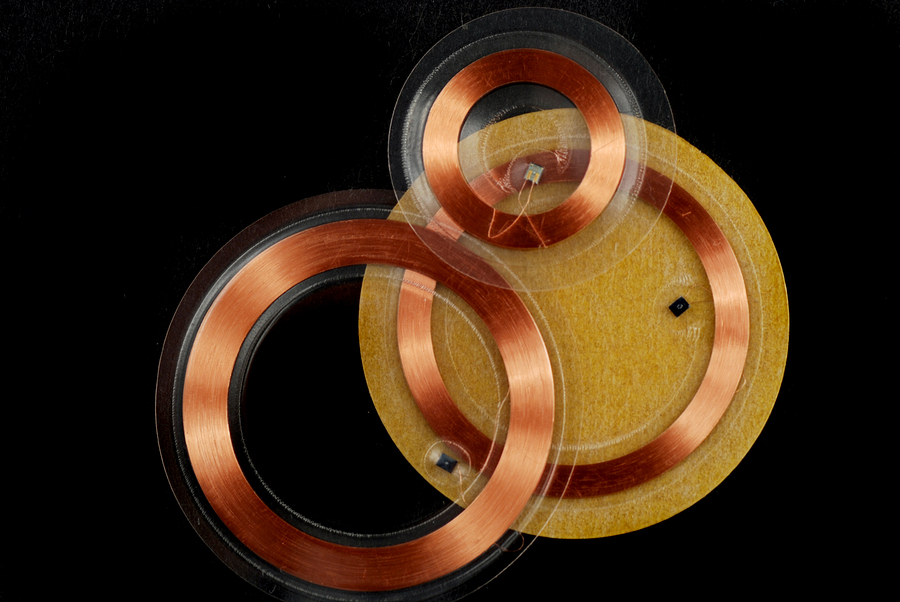

RFID tags can be insert molded into various shapes to fit your specific applications such as custom containers, tags, plugs, threaded caps, buttons or any other part that needs to be tracked or identified. RFID tags can be injection molded in many thermoplastic resins to fit the application. Low frequency (LF), high frequency (HF) or UHF configurations are available.

If you have questions or need further assistance please contact us at 281 489-4292 or use our Contact Form.