1. Application – Begin with a thorough understanding of the product application.

-

- Where it will be used?

- How long it needs to last?

- What environmental and mechanical conditions will the product be exposed?

- What cosmetic or other performance characteristics do you desire for your product?

- What economic or cost constraints do you have for your product?

2. Material Properties – To be able to effectively evaluate and select materials it is important to have a general understanding of plastic material mechanical performance, chemical resistance, environmental requirements and the technical standards used to measure performance. UL IDES provides an excellent resource to understand these properties. UL IDES Material Properties.

3. Select a material family – Once you have a good understanding of the application and material properties you can begin narrowing your search to a family of plastic resins. You can use the following charts to help narrow your search to a few materials or review summary descriptions of the most commonly specified materials in our Thermoplastic Material Guide below.

4. Specify Material – Use the UL IDES Materials resource to pull up manufacturers’ material data sheets to review specific materials and match their performance to best suit your application. Additional performance can be achieved by compounding materials with alloys, fillers, and additives. The Engineers at Texas Injection Molding help guide our customers through the complex material selection process to find cost-effective solutions with the right performance characteristics.

We have selected some of the most common commodity, engineering and performance grade materials and are providing the following briefs and application sheets to help in selecting the best material for your application. If we can be of assistance with your project call us at 281 489-4292 or use our Contact Form.Thermoplastic Material Selection Guide

Commodity:

Polypropylene Injection Molding (PP): PP is a low cost, lightweight polymer that has excellent chemical resistance. Polypropylene is tough, has good resistance to fatigue, and can be reinforced with glass fiber or minerals to enhance mechanical properties.

High Density Polyethylene (HDPE): A versatile, workhorse thermoplastic polymer ideal for consumer and industrial products, toys, storage containers, sporting goods, appliances, and milk crates.

Low Density Polyethylene (LDPE): LDPE is a softer version of HDPE and popular in manufacturing consumer and industrial products.

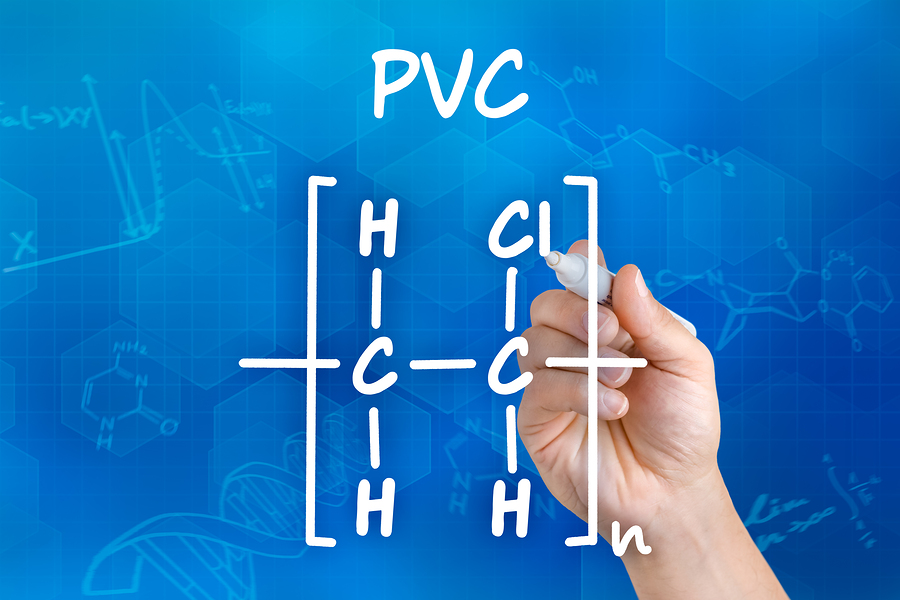

Polyvinyl Chloride (PVC): PVC is lightweight compared to metal pipe that it has replaced in many applications, but is heavier than most other grades of plastic. PVC is widely used in water, sewer, windows, siding, and other building products.

Polyethylene Terephthalate (PETE): PETE is very strong for its lightweight. It is most commonly used thermoplastic polymer in the world and is better known by the trade name “polyester.”

Polystyrene: Commonly used for office products, food processing and storage, consumer products, and construction.

High Impact Polystyrene (HIPS): HIPS is a versatile, economical, impact-resistant plastic.

Engineering:

ABS Plastics Injection Molding: ABS is a common engineering thermoplastic that has good impact strength and toughness along with mechanical and electrical properties that make it ideal for a variety of plastic injection molding applications.

Acrylic Injection Molding (PMMA): Known commonly by the Plexiglas® and Lucite ® trademarks, acrylic – or PMMA (polymethyl methacrylate) – is a glass substitute that offers many exceptional properties in plastic injection molding.

Polyurethane (TPU): Resilient, versatile and strong, thermoplastic polyurethane (TPU) is available in ether and ester-based formulations with a very broad range of hardness properties.

Nylon (PA): Few plastics combine the versatility, value, and mechanical performance of nylon. The most common forms of Nylon are the PA 6 and PA 66 versions. Nylon has excellent strength, stiffness, heat resistance, wear-resistance and lubricity, chemical resistance to hydrocarbon.

Thermoplastic Elastomer (TPE): TPE combines the valuable and versatile properties of rubber and plastics.

Thermoplastic Polyurethane Elastomer: TPU is a tough, durable plastic well-suited to applications that demand the elasticity of rubber and high tensile and tear strength.

Engineering Thermoplastic Alloy: An alloy that offers enhanced strength and toughness in various properties.

Polycarbonate (PC): Polycarbonate is a rugged, engineering-grade thermoplastic that offers exceptional impact resistance and strength in many demanding applications, like bulletproof glass.

Polybutylene Terephthalate (PBT): A polyester resin, PBT offers good electrical, mechanical and thermal properties with excellent chemical resistance to a variety of chemicals including aliphatic hydrocarbons, oil, grease, dilute acids and bases, and detergents.

Performance:

Polyetherimide (PEI): Valuable in the medical, electronics, and other fields that demand exceptional strength and rigidity in high-heat applications, PEI is a high-performance polymer offers excellent dimensional stability, combined with broad chemical resistance. PEI is ideal for hot air and water environments.

Polyphenylene Sulfide (PPS): PPS has the broadest resistance to chemicals of any engineered thermoplastic. PPS is exceptionally resistant to flame, acids, ketones, alkalis and hydrocarbons, making it an ideal thermoplastic for challenging corrosive, high-heat, and chemically strenuous environments.

A Strategy that Delivers Service

Texas Injection Molding follows a simple strategy founded on People, Process and Technology. Our strategy in supported by a culture of respect and genuine concern for others and is the “secret sauce” that makes us different.

People

- Our team of plastic engineering professionals support customer applications with decades of industry experience

- Our tooling and technical application team provide solutions to product revisions and advancements in automation and assembly.

- We partner with the world’s leading resin manufacturers and custom compounders to deliver deep technical resources in the areas of custom resin applications and testing.

Process

- Manufacturing operations are certified to ISO 9001:2015 standards

- Manufacturing processes for every part are optimized and qualified to repeatable standards prior to releasing to production.

- Molding machines and tooling are calibrated and managed to established MRO standards

- Materials certified and lot tracked by barcode

- Every machine and key processing parameter is measured, reported and recorded in real time.

Technology

- We provide and maintain modern production technology and tools for our processing technicians to work efficiently.

- Our systems provide real time access to inventory, scheduling, machine utilization and many other factors to help us meet our client requirements.

- Broad press range to accommodate 55 to over 800 tons

- Automation inside and outside the tool, printing, sonic welding, assembly and custom packaging.