Texas Injection Molding Announces Construction of New Injection Molding Plant

Texas Injection Molding, a Houston-based manufacturer of plastic injection molded products, today announces that it has purchased a 6.78 acre tract from Wycoff Development Corporation and will build the first phase (64,000 sf) of a 94,000 square foot modern manufacturing facility. The new location will be at 11015 Bay Commerce Drive, Houston, Texas 77034, located at the SE corner of I-45 South and the Sam Houston Tollway. We are proud to call Houston our home and pleased to be a leader in one of the largest manufacturing communities in the United States.

The new facility will be operational in 2020 and provide additional manufacturing capacity to support growth in a variety of industrial sectors. The $6.5 million project is financed by Bank of America through a 504 SBA loan.

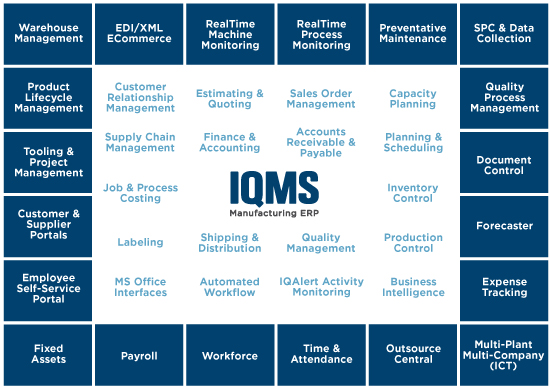

Texas Injection Molding was founded in December 2013 through the acquisition of B-Side Plastics. Starting with 10 molding machines and 22 employees, Texas Injection Molding has assembled a tremendous leadership and engineering team, added a full-service tool and die shop, certified operations to ISO 9001-2015, implemented industry leading ERP software for managing real time production information, and invested more than $3 million in plastic processing machinery. “This investment in modern molding technology and automation has put our team members and company in a position to advance the success of our customers businesses with competitive and high-quality injection molded components.” Scott Kelley, President of Texas Injection Molding.

Texas Injection Molding is built on a strategy of People, Process and Technology. We recognize the importance to provide an efficient work environment where our team members can grow in their careers. The new facility will be crane served and fully climate controlled. Texas Injection Molding has awarded Conair, a leading manufacturer of plastics processing and material handling equipment, the contract to install a central material handling system and closed loop process water to ensure consistent manufacturing processes. Texas Injection molding currently operates 23 presses and employs 94 employees. Scott Kelley, “We are very proud of our team and are excited to see our customers and teammates prosper with the new manufacturing facility.”