Plastics Engineering is the foundation that Texas Injection Molding is built upon. We lead with engineering on all plastic injection molded projects and pride ourselves in assisting our customers to solve complex plastics design and engineering problems.

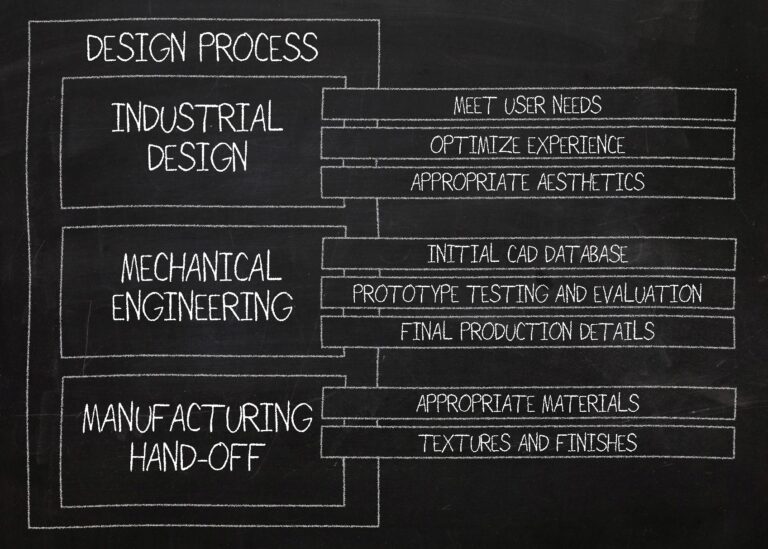

Product Design

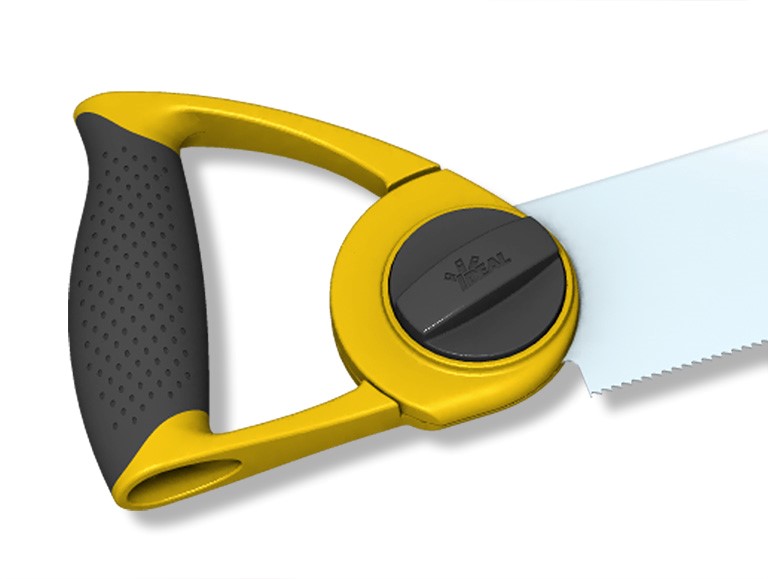

The Engineers at Texas Injection Molding draw upon the collective experience of working closely with industrial designers to develop hundreds of products for a wide variety of industries and molded plastic product applications. We actively assist contract industrial design firms and client in-house engineering to evaluate plastic part design to enhance plastic part performance and manufacturing efficiencies.

For general guidelines, please see out Plastic Design Guide.

Material Development

Our depth of experience has allowed us to work with the full range of commodity and engineering thermoplastics in simple products to applications demanding performance in extreme environments. Many of the world’s leading commodity plastic resin manufacturers are located on the gulf coast. We are strategically located close to these manufacturers providing access to material, plastic engineering resources and a vast network of plastic engineering and testing facilities supporting the development of polyethylene and polypropylene polymers. We also collaborate regularly with the world’s leading engineering resin manufacturers and plastic compounders on plastic material development for specific product applications.

These partnerships provide additional support from polymer engineering laboratories and plastic resin material development experience that we offer to our customers.

Tooling

As a custom manufacturer of plastic components, we manage the tool design and build of low volume simple geometry injection molded pats to fully automated, high volume injection molded parts with complex geometry and aggressive materials. We build to the Society of Plastic Industry, SPI, Mold building standards. Where appropriate in lower volume applications our engineers will utilize family tools with hand-load inserts for undercuts and threaded components. Slides and automated unscrewing devices are use the hydraulic core pull feature on the injection molding machine where cost effective to produce undercuts and threaded parts.

Production, Assembly and Automation

Every injection molded part we manufacture is unique and requires engineering to think and plan beyond the plastic part to include the

fully finished assembly. During the cycle time between injection molded parts, we incorporate decorating, machining and decoration and packaging at the molding machine. Our engineers consider the secondary operations and cycle time of the plastic molded part when designing the tool to build in manufacturing efficiencies at the molding press. For complex assemblies that require multiple components, our Industrial/Systems Engineers lay out the assembly process, engineer and build custom fixtures and assembly processes to reduce cost and increase throughput.

If we can help you with your design for manufacturing (DFM) project please call us at 281 489-4292 or use our Contact Form.